A probe can be as simple as a nail, a spring and a length of copper wire. I had some unused items in the shop which led to a bit of overkill. The large metal thing in the photo is an old PC power supply. Over to the left is a board to read pulses from a photo interrupter. In the centre is a dial indicator with a metal tang screwed to the top of the plunger. This tang breaks the beam of a photo interrupter whenever the plunger is forced upwards. The dial indicator is handy for quickly finding high/low spots in a sheet of material. For actual probing the nail and spring mentioned earlier would serve the same function.

This is the bowed wood that was probed. The shiny bit is a quarter to give a sense of scale. A size for the engraving and a centre origin point were decided on at this time, the origin point was marked with a felt pen. The reason for marking the origin will become clear in the next step. To probe a grid of points smartprobe.ngc was used, this is included with the Linuxcnc package. The probe work piece coordinates were zeroed at the the centre of the material. Z zero is set to the photo interrupter trigger position at this origin which is also the high point of the material.

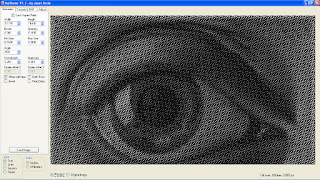

The text file created looks like this:

-3.000000 -2.750000 -0.404709

-2.800000 -2.750000 -0.346447

-2.600000 -2.750000 -0.292887

-2.400000 -2.750000 -0.244701

-2.200000 -2.750000 -0.201554

etc etc etc. It's pretty dull reading but it can be put to use or at least something resembling a use. It's time to visit ScorchWorks.

http://www.scorchworks.com/

The 2 Scorch programs used in this post are F-engrave and G-Code-Ripper.

The smiley moon started as an SVG from OpenClipart. F-engrave needed a DXF file so InkScape was used for the file conversion. I won't go into how the g-code file was created in F-engrave except to say it's about as simple as this type of software gets. The critical point is the origin and scale are the same as the grid probe file.

With a probe text file and an engraving g-code finished it's time for G-Code-Ripper.

A: open g-code file

B: open probe text file

C: save the adjusted file

That's it.

Remember the felt pen mark made earlier ? That's where the cutter was touched off for the engraving work piece coordinates. It was done this way because the probe wasn't in the spindle or even near it.

Anyone tempted to try this is advised to go to YouTube where there are several examples. The software has a clever probe function which wasn't used in this post