(with a bit of help from Inkscape and bcnc)

Warning: This post isn't beginner-friendly

Inkscape is being used for all the text work. When using cursive font it can help to use a workflow like this: Path > Object-to-path; Object > Ungroup; Path > Union

Regardless of how this is done there will be a need for node editing and joining. When editing nodes give some thought to the diameter of the tools. A tool can't cut an inside feature smaller than the tool radius so it makes sense to alter features to match this reality at the drawing stage. The simple border was also drawn in Inkscape and nicer examples are available on sites like OpenClipArt.org

Import each 'word' as a separate string to the Draft Workbench to keep them easy to manipulate in FreeCad. After importing a string of text select all and then do a Modification --> Draft-to-sketch.

The model is made up of 4 extrusions and a cube. The rectangular border is 0.25" proud of the base cube. The "HOTEL" text is extruded to be 0.125" proud of the base. The 2 cursive text strings are extruded to stand 0.25" proud of the base. All parts are aligned and fused in Part Workbench using boolean unions.

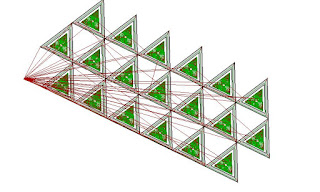

In the Path Workbench several tool paths will be needed and the UI is going to get messy. An operation's back plot can be hidden by selecting the operation in the tree view and setting "Active" to "False" in the data panel.

The first operation was adaptive clearing using a 0.25" end mill. Select the face of the border and then the faces of the 2 cursive text strings. The "Cut Region" selection is "Outside" and the "Force Clearing Inside-Out" option is selected. The depth of this cut is -0.125". If all goes correctly this operation should not attempt to profile the "HOTEL" text string.

The next operations used a 0.125" end mill at the -0.125 depth. These operations are finishing profiles on the cursive text and optionally the internal pockets in the cursive text. Pocketing the letters at this stage is only mandatory if planning to apply paint/stain before continuing to the next depth of cuts. In this example the "e" in angel and an "o" in nook need to be pocketed to allow all the visible parts of the letters "O" and "E" to be painted.

| |||

| Camotics Simulation |

Camotics spotted a missing pocket in the "e", running the sim was worthwhile.

Before any cutting, gold spray paint was applied. Then a paint mask was used, in this case the mask was self-adhesive shelf liner. After all the cuts at the -0.125" depth were complete green spray paint was applied. The paint mask protected the gold paint from the green spray.

I try to keep these posts short so continued in part 2.