Need something to decorate your cnc workspace ?

Here's something simple that only needs a bit of flat material and whatever paint/stain you have on hand.

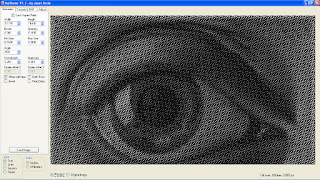

On the left is M.C. Escher's "Eye". The item to the right is a reproduction of the sexiest automobile ever produced (in my biased opinion). The eye is a piece of varnished ply, spray painted black before carving. The Jaguar is a piece of shelving veneered with white melamine, blackboard paint fills in the dots. Both were cut with a 90 degree v-bit.

The effect created is hard to photograph, easier to explain. Up close it's pattern of dots, at a distance the dots become an indistinguishable part of the image. These work best outdoors or in a large room. Inch size dots on a building size canvas would be an awesome display.

The software used is full of features and at the same time simple enough to be self-explanatory. Thank you Jason Dorie, here's the link:

http://jasondorie.com/page_cnc.html

Friday, 28 September 2018

Friday, 14 September 2018

Edge Lit LED Engravings

The material used is 3/8" cast acrylic from an unknown manufacturer. Other plastics may also work but cast cuts nicely and the thicker material adds visual depth.

The dxf file can be found here:

http://s3.cnccookbook.com/free-dxf-files-vehicles.html

The cutting file was created in Fusion 360. The original dxf file was edited to contour around the top of the car. The contour was cut with a 1/4" 2 flute end mill. The etching was done with a 'trace' toolpath using a 90 degree v-bit cutter at 0.012" depth. A depth of 0.006" or 0.008" would have created finer detail making tidier work of the CAMARO text. Notice the text (and the car) are a mirror image because the engraving is on the 'back side', or in other words the display side is an uncut surface.

The Lotus Bloom engraving was a test cut. It's the top of a laminar fountain nozzle which may be described in a future blog entry.

The LED lights are cut off a spool of strip lighting commonly found on EBay or Amazon. A two section piece can be seen in front of the Camaro in the photo below.

Bad photo background, what looks like dirt or scratches is really the dust shoe brush on my router. The power is supplied by a 12V wall wart. The 4 position switch was salvaged from a multi-function flashlight. The colors available with this switch are red, green and white. (Is white a color?).

The dxf file can be found here:

http://s3.cnccookbook.com/free-dxf-files-vehicles.html

|

| Screenshot from Fusion 360 |

The Lotus Bloom engraving was a test cut. It's the top of a laminar fountain nozzle which may be described in a future blog entry.

The LED lights are cut off a spool of strip lighting commonly found on EBay or Amazon. A two section piece can be seen in front of the Camaro in the photo below.

Bad photo background, what looks like dirt or scratches is really the dust shoe brush on my router. The power is supplied by a 12V wall wart. The 4 position switch was salvaged from a multi-function flashlight. The colors available with this switch are red, green and white. (Is white a color?).

Friday, 15 June 2018

Nearly free tramming bar

|

| the black object protruding from the bar is a common dial test accessory |

|

| checking perpendicularity, more commonly known as tramming |

Materials:

A piece of hardwood

A 1/4-20 bolt with the head removed

A 1/4-20 wing nut

A 1/4-20 nut & bolt to fasten the dial indicator

Why 1/4" bolts? It's a common router collet size and also fits the mounting hole on most cheap dial indicators.

| ||||||||

| finding the centre of a circular object |

It's for comparative measurement so as long as it's repeatable it's good enough. For the same reason the cheapest of indicators should work as well as pricey units. In a pinch a bent piece of rod and feeler gauges can replace this whole apparatus

Wednesday, 13 June 2018

$2 Router Table Clamps

This project is cheap fun assuming you have available scrap or scrounging skills.

The original idea was spotted on Thingiverse, here's the link:

https://www.thingiverse.com/thing:776

Materials used:

1/2" birch plywood https://www.menards.com/main/building-materials/panel-products/specialty-panels/hardwood-panels/1-2-x-20-23-x-20-23-c2-russian-birch-plywood/1254000/p-1452209920854.htm

3/4" hardwood dowel (to make the pivots)

1/4-20 threaded rod

1/4-20 nuts

1/8" hardwood plywood (to make the nut retainers)

1/8" HDPE sheet (to make the plastic washers)

A scrap piece of birch flooring (to make the knobs)

Woodglue

The knob in the centre of this image has a 1/4-20 nut embedded just slightly deeper than flush. The recess for the nut is a hexagon pocket cut with a 1/8" diameter bit which leaves a bit of material where there should 6 sharp corners, this provides a nice interference fit. Barely visible leaning against the knob is a wooden washer, this will be glued to the knob to act as a nut retainer. To the right of the knob is a threaded rod and an "E-Z LOK" threaded insert. The inserts have been installed from the underside of the table surface. Every hole seen in the table above has a threaded insert installed.

An exploded view. The wooden washer is glued to the knob to act as a nut retainer. In practice the nut may fit tight enough in the knob to make the retainer unnecessary. If the knob is hardwood (I used birch hardwood) the knob itself could be tapped for threads eliminating the nut. The pivot has been milled to provide a flat surface, this increases the holding power of the knob assembly.

WARNING: These clamps will collide with the router if you get too close. For added clearance a bolt can replace the threaded rod and knob.

The original idea was spotted on Thingiverse, here's the link:

https://www.thingiverse.com/thing:776

Materials used:

1/2" birch plywood https://www.menards.com/main/building-materials/panel-products/specialty-panels/hardwood-panels/1-2-x-20-23-x-20-23-c2-russian-birch-plywood/1254000/p-1452209920854.htm

3/4" hardwood dowel (to make the pivots)

1/4-20 threaded rod

1/4-20 nuts

1/8" hardwood plywood (to make the nut retainers)

1/8" HDPE sheet (to make the plastic washers)

A scrap piece of birch flooring (to make the knobs)

Woodglue

The knob in the centre of this image has a 1/4-20 nut embedded just slightly deeper than flush. The recess for the nut is a hexagon pocket cut with a 1/8" diameter bit which leaves a bit of material where there should 6 sharp corners, this provides a nice interference fit. Barely visible leaning against the knob is a wooden washer, this will be glued to the knob to act as a nut retainer. To the right of the knob is a threaded rod and an "E-Z LOK" threaded insert. The inserts have been installed from the underside of the table surface. Every hole seen in the table above has a threaded insert installed.

An exploded view. The wooden washer is glued to the knob to act as a nut retainer. In practice the nut may fit tight enough in the knob to make the retainer unnecessary. If the knob is hardwood (I used birch hardwood) the knob itself could be tapped for threads eliminating the nut. The pivot has been milled to provide a flat surface, this increases the holding power of the knob assembly.

WARNING: These clamps will collide with the router if you get too close. For added clearance a bolt can replace the threaded rod and knob.

Thursday, 31 May 2018

hand trace to gcode

|

| hard to measure slopes and curves |

Anyone reading a CNC blog will be familiar with creating a drawing in CAD but what if the aim is to reproduce an item that's difficult to define with a few caliper measurements ? The picture on the left is part of a toy truck.

It's possible to trace the photo itself in software. It's also possible place a 3D object on a flat bed scanner. In this example a quick trace was was done with fine tip marker. The trace was placed on the scanner and the resulting b+w image opened in Inkscape

| ||

| vector graphic on left, imported scan on right |

The dxf can be imported into CAM software to create the gcode file. Fusion 360 was used for CAM. As mentioned earlier the digital camera image can be imported directly into Fusion for tracing, I am simply more comfortable with the Inkscape tracing features. The picture below is a test cut done in a piece of scrap.

|

| pictures or it didn't happen |

Sunday, 29 April 2018

the whittler machine

This blog isn't dedicated to building machinery, other websites and blogs do that much better than I could ever accomplish. Included here is a short description of one of my DIY builds. This machine is a fixed gantry cnc router based on other designs but not a copy.

The travels are 32" x 18.5" x 7.5"

|

| A look beneath the skin |

|

| It's dirty but looks just as crude clean |

|

| press fits to avoid welds |

|

| gantry carriage in Fusion 360 |

The travels are 32" x 18.5" x 7.5"

Subscribe to:

Posts (Atom)